High performance creels for economical production of top-

and other state-

The HUYS creels are used in a very large application span

- Creels for sectional warpers, direct warpers and beaming machines

- Creels for direct feed of weaving & knitting machines

- Creels for narrow-

fabric looms - Special applications / nonwovens

We can deliver bobbin creels for clients’ every requirement. The basic creels are available in four basic configurations.

Different tensioners are available for each application. From the finest polyester monofilament to coarse carbon fibre yarns; for each application we have the right solution. In addition the creels are capable of satisfying all specific customer requirements with appropriate options.

If the run-

To satisfy every quality and performance demand HUYS has a full range of creels for sectional & direct warping equipment and knitting machines.

HUYS bobbin creels for universal use

Fixed frame creel with travelling cleaner

Four basic creel models

- Fixed frame creel

This is one of the most widely used types of creel. This creel features a rugged steel construction with suspended tensioner frames. This design leaves the floor free for cleaning and offers excellent accessibility and handling.

By moving the tensioner frames laterally, a loading gangway is created between the packages and the tensioners. Likewise the distance from package to tensioner can be adjusted for optimal balloon formation. The frames can be moved by hand or optionally with motorized run-

- Retractable truck creel

The packages are loaded on double-

- Magazine creel

A magazine creel allows continuous, non-

This creel is used for high volume and long run production where a high warper or beamer efficiency is essential.

The next set of packages to be run can be loaded and prepared while the warper is running the previous set. When the running packages are empty, the package frames can be rotated to bring the new set of packages into the active position. The rotating frames have a locating catch-

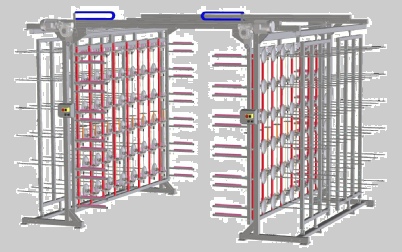

- Swivel frame creel (creel with rotating frames)

Swivel frame creels are used for warping successive sets of equal length yarn packages with minimum stop time and maximum production. This creel is particularly suited for large packages of filament yarn. While the package frame is being run off on one side, the new lot can be creeled on the other side at the same time.

3-

This creel is available with inside or outside yarn creeling.

Platform creels for insertion of glass fiber yarns in nonwovens

HUYS creels for special applications

Through the years HUYS has acquired a large expertise in the field of creels and associated peripherals and accessories. As a result HUYS is in the position to offer you an equipment solution for every creeling task. Our ability to balance process requirement, technical performance and financial constraints make us the ideal partner for any fibre unwinding project.

We welcome the challenge of the textile-

Self compensating tensioners (type Karl Mayer) →

The yarn tension remains constant on a given setting, both with cops and conical wound or cross-

Electromagnetic tension system (Appalachian) ↓

The YTC tensioning system from appalachian is based on electromagnetic technology and controlled by a menu driven touch-

Each tensioner has a separate motor for tension disc cleaning. The tension is kept constant through the whole speed range because the electronics have a feedback system that levels the yarn tension from start-

The yarn is going in a soft angle path through the tensioner. Therefore this system treats the yarn gently and reduces variations in the yarn structure and the number of fibre breaks. Versatile and flexible, the system can be applied to an extraordinary range of textile yarns and yarn counts, producing warp sets for exceptional weaving and superior warp knitting.

Each tensioner has a photo-

Last update: 8/05/2020

Self compensating tensioner

Creel with the electromagnetic tension system from Appalachian

Creel with rotating frames for upholstery fabrics from recycled yarns (Beaulieu, Belgium)

Creel for geotextiles, 1.000 -

© 2020 HUYS • All rights reserved

Creel installation in France for delicate fibres: silk, cashmere

BELGIAN QUALITY

Textile technology

Creel with Appalachian tensioners for narrow width fabrics (Rathgeber, Germany)

Creel installation for a Robotic warping machine: Robowarp PB9 from Prashant.

Beaulieu International Fabrics; Upholstery fabrics from recycled yarns.